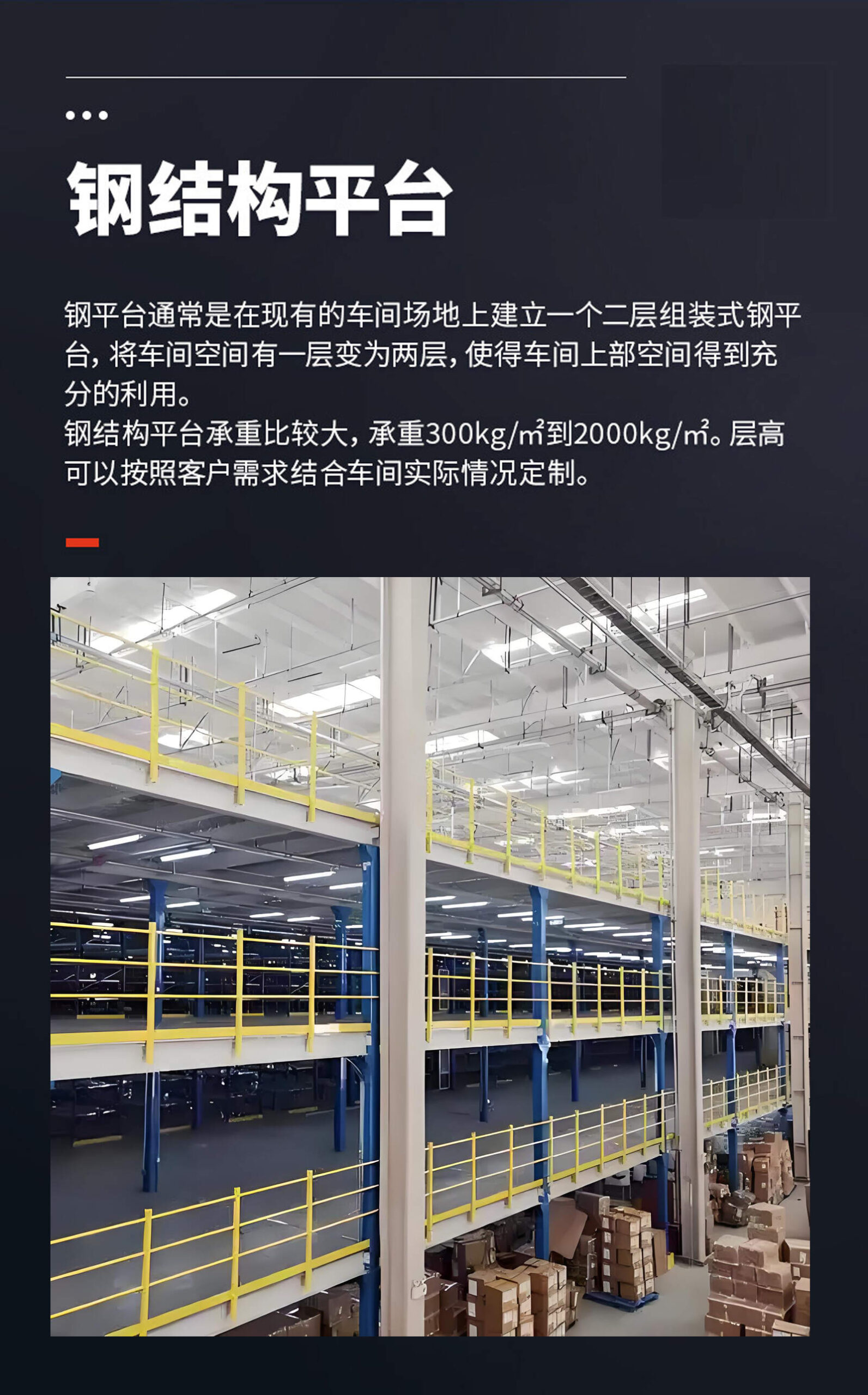

Steel structure platform racks, also known as steel structure platforms, work platforms or steel platform racks, are a multi-layer work platform system built with steel structures. They are usually built inside the original warehouse or workshop, and use the upper space of the building for secondary development. Its core advantage is that it can achieve vertical expansion of space without changing the original building structure, thereby significantly improving the utilization rate of unit area. Steel structure platform racks are widely used in various industrial scenarios, especially in high but underutilized factories, warehouses or distribution centers.

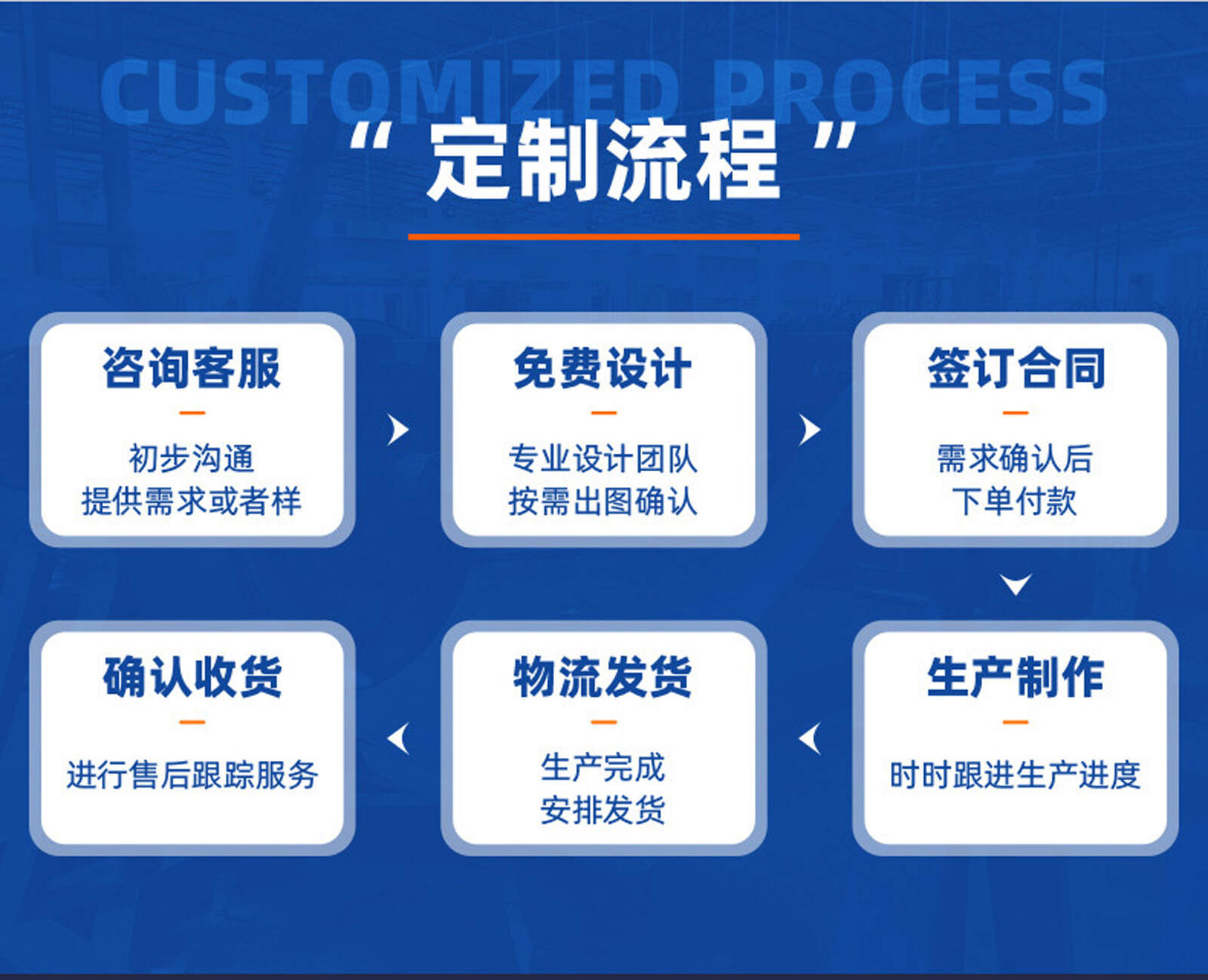

Leave a message

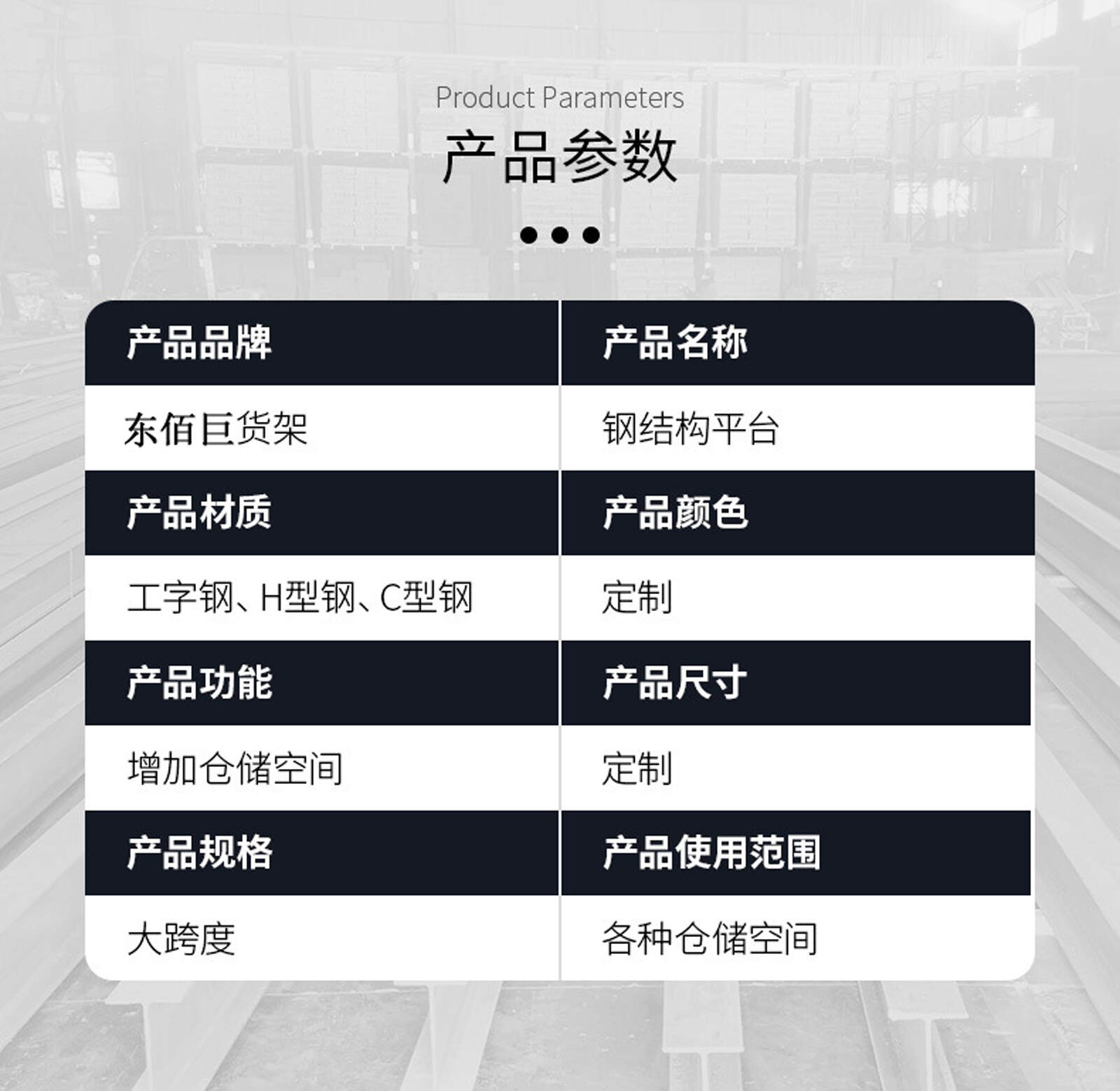

Product Details

Product selling points:

No welding required, flexible structural design, all components are connected by high-strength bolts, no on-site welding is required, no need to rely on the original factory columns and walls, easy to disassemble and assemble:

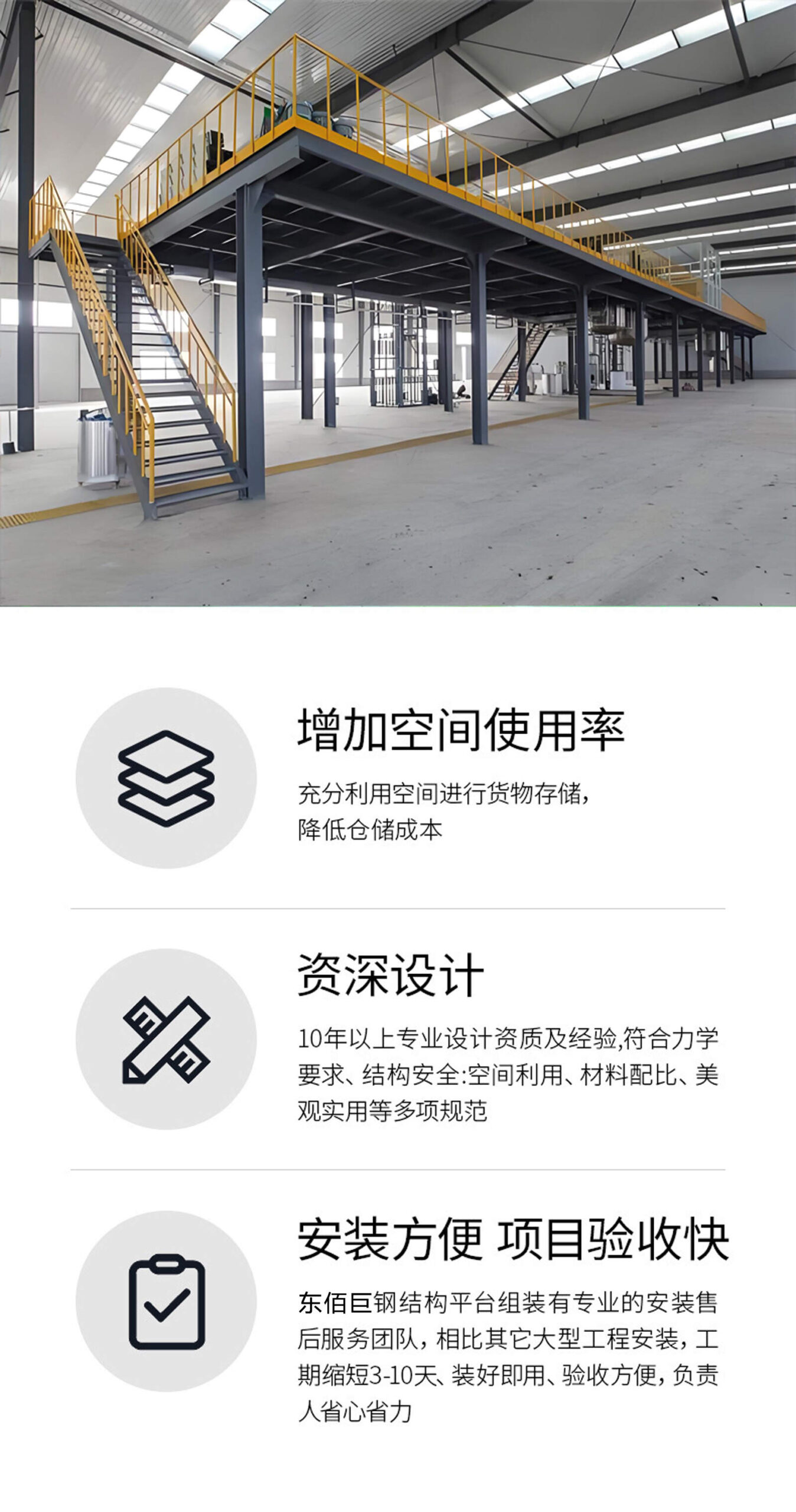

Senior Design:

More than 10 years of professional design qualifications and experience, in line with mechanical requirements, structural safety:

space utilization, material ratio, aesthetics and practicality and other specifications:

Easy installation:

Fast project acceptance Dongbaiju steel structure platform assembly has a professional installation and after-sales service team. Compared with other large-scale project installations, the construction period is shortened by 3-10 days, it is ready for use after installation, and the acceptance is convenient, which saves the person in charge worry and effort.

A professional design team of more than 20 people, providing on-site measurements nationwide and free design solutions

Intelligent high-bay warehouses utilize automated equipment such as stackers and AGVs to achieve 24-hour uninterrupted operations, with efficiency 5-10 times that of manual labor. Stackers move at a speed of 3 meters per second with a positioning accuracy of ±5 mm, enabling high-density storage and rapid operations, improving storage capacity and operational efficiency.

The shelf height of the intelligent three-dimensional warehouse can reach 40 meters, and the storage capacity per unit area is increased by 5-10 times, which significantly reduces the land rental cost. In addition, the automated process reduces manual operations and reduces labor costs.

Intelligent high-bay warehouses are highly automated and can execute tasks quickly and accurately. Real-time data monitoring and tracking functions enable real-time monitoring of inventory status, transportation status, and equipment operating conditions, improving the accuracy and reliability of cargo handling.

Intelligent three-dimensional warehouses enhance data analysis capabilities through information systems and big data technologies, provide strong support for warehouse management decisions, optimize inventory management strategies, and improve capital turnover efficiency.

The intelligent three-dimensional warehouse system can quickly adjust storage strategies according to business needs, support a multi-variety and small-batch production model, enhance the company's market responsiveness, and with the development of technology and market changes, the system can be continuously upgraded and optimized.