Medium-duty racks are a type of storage racks and are classified and named according to the load capacity of the racks. According to this classification principle, medium-duty racks are between light-duty racks and heavy-duty racks, hence the name medium-duty racks.

Leave a message

One-stop warehouse organization expert, delivery to downstairs

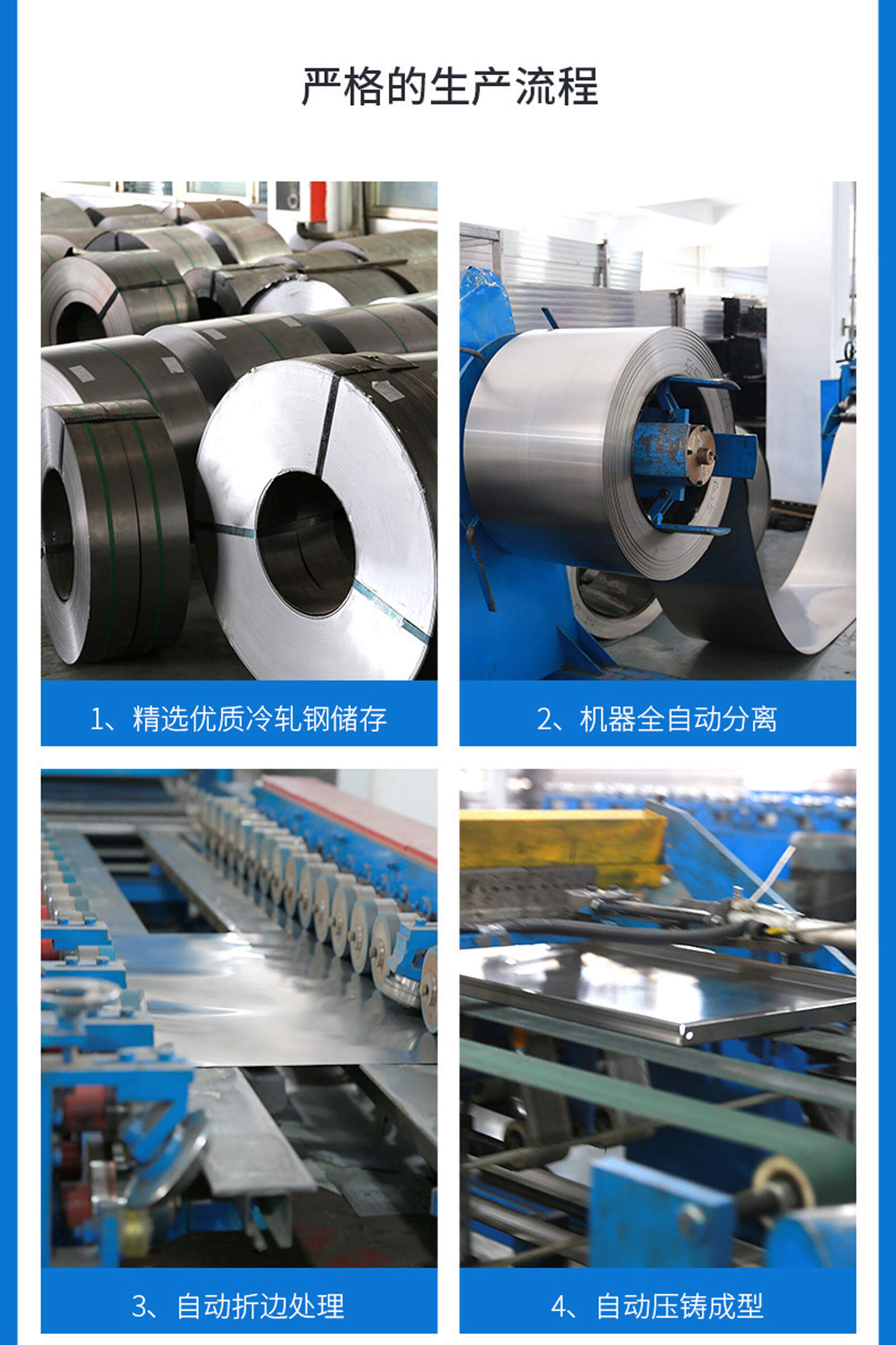

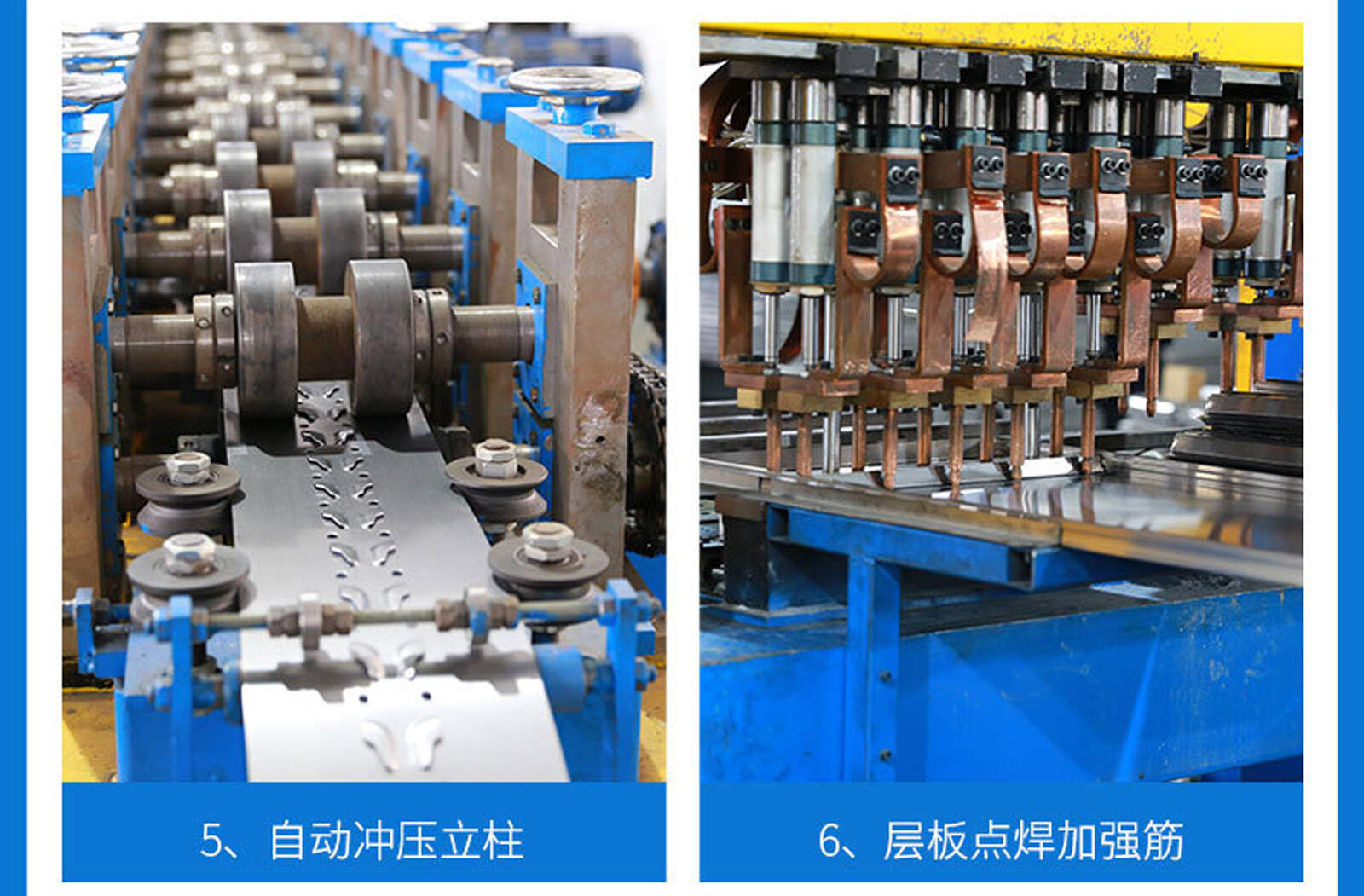

Selection of high-quality cold-rolled steel:

Cold-rolled steel is made from hot-rolled plates, which are rolled at room temperature and crystallization temperature to form cold-rolled steel plates with smooth and bright surface and more precise thickness.

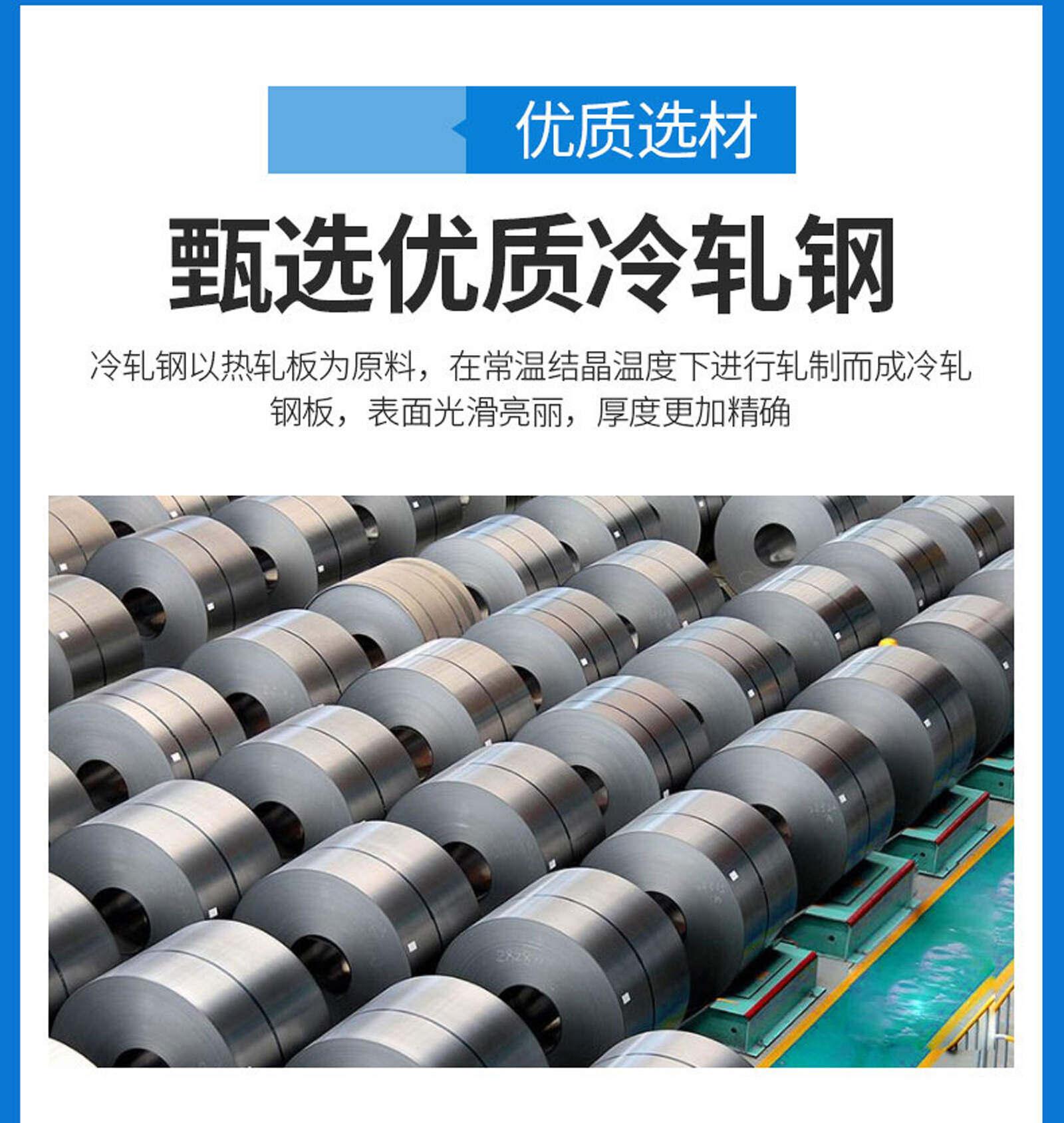

Quadruple craftsmanship quality inheritance:

Each set of shelves must be strictly forged through multiple processes, durable, paint-resistant, deep craftsmanship and corrosion resistance

Service life test:

Selected high-quality cold-rolled steel plates, cut and polished, and then treated with oil silane, high-temperature air drying and electrostatic spraying technology, the service life is longer than that of ordinary shelves on the market!

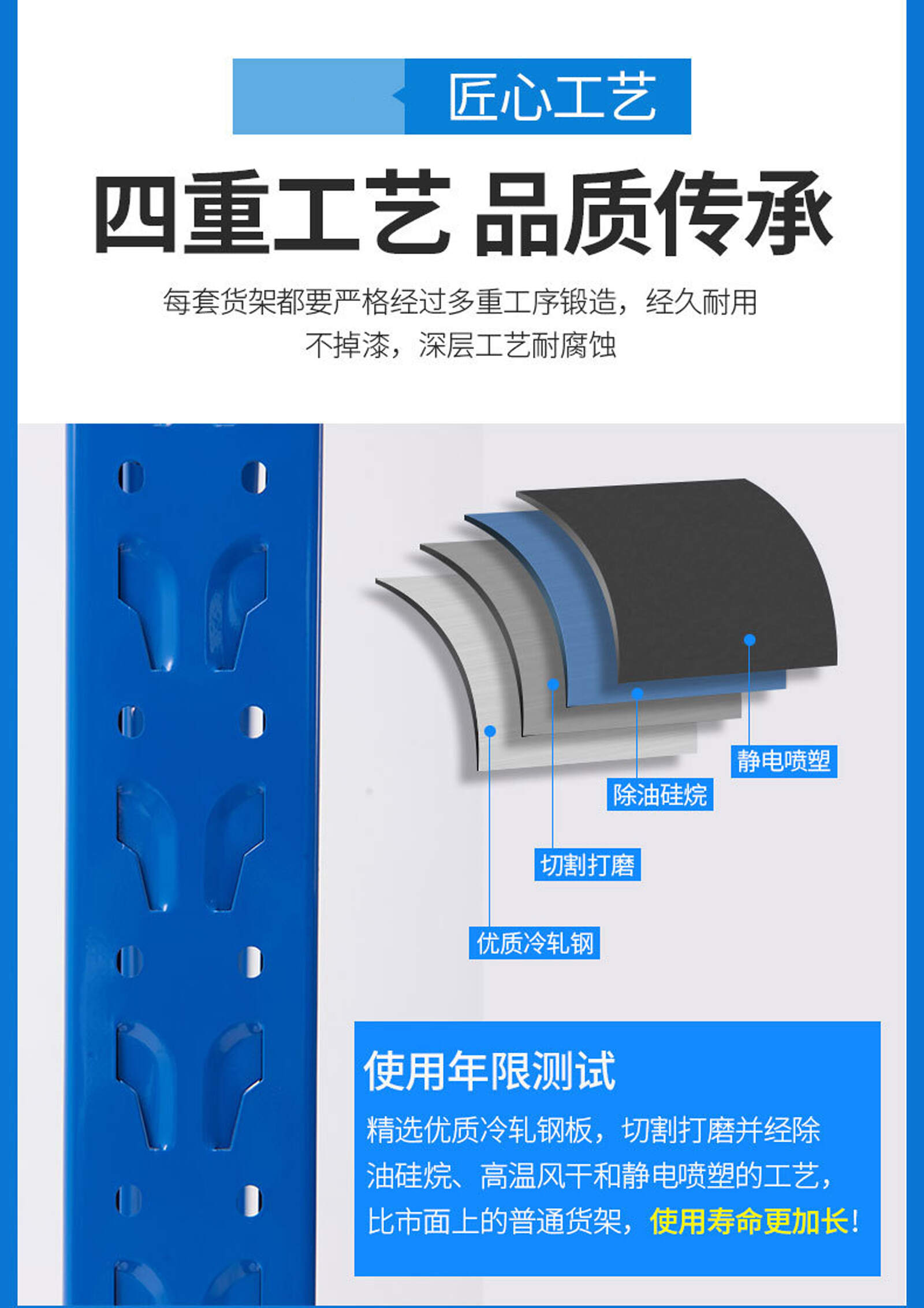

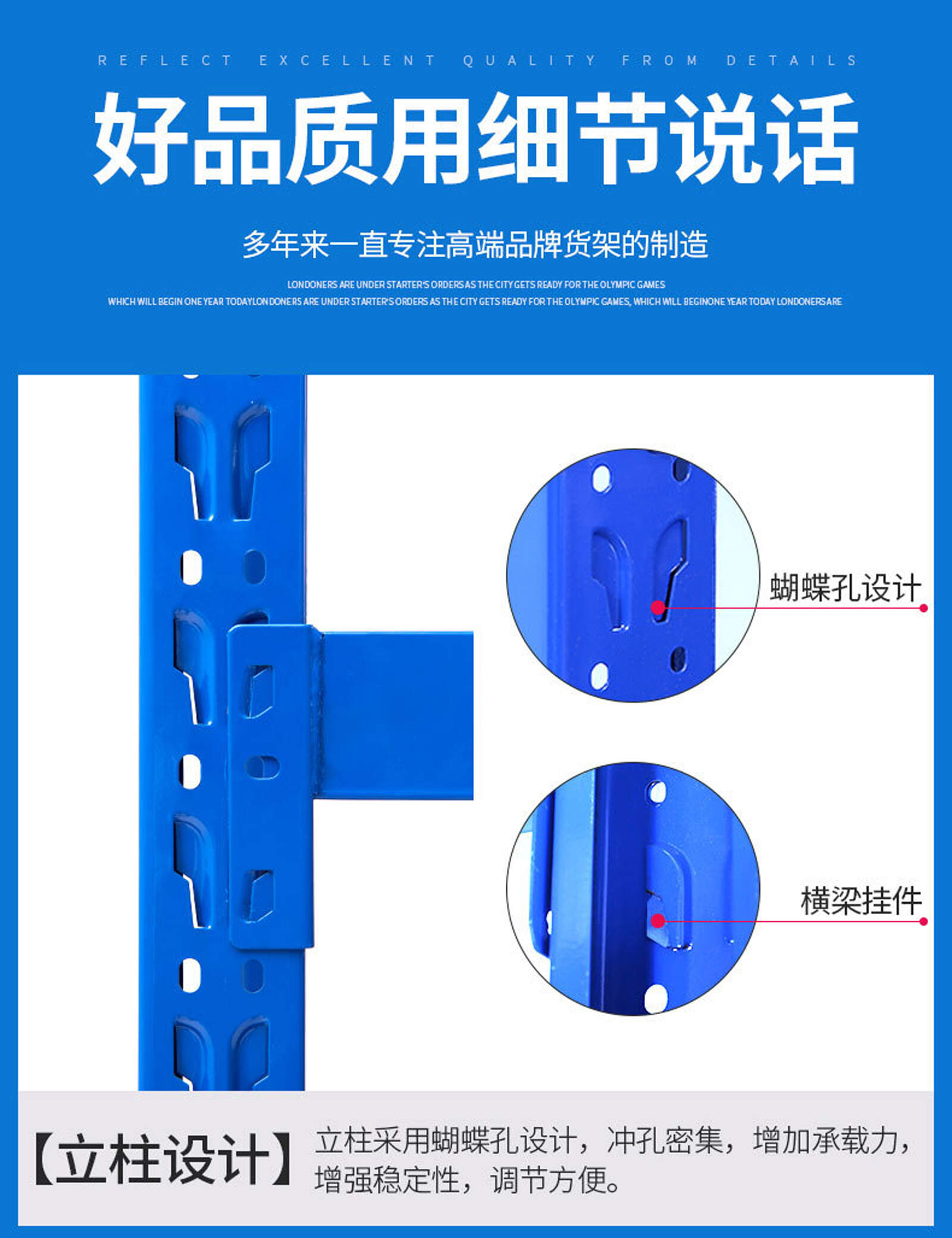

Good quality speaks for itself in details:

We have been focusing on the manufacturing of high-end brand shelves for many years.

Column design

The column adopts butterfly hole design with dense punching to increase bearing capacity, enhance stability and facilitate adjustment

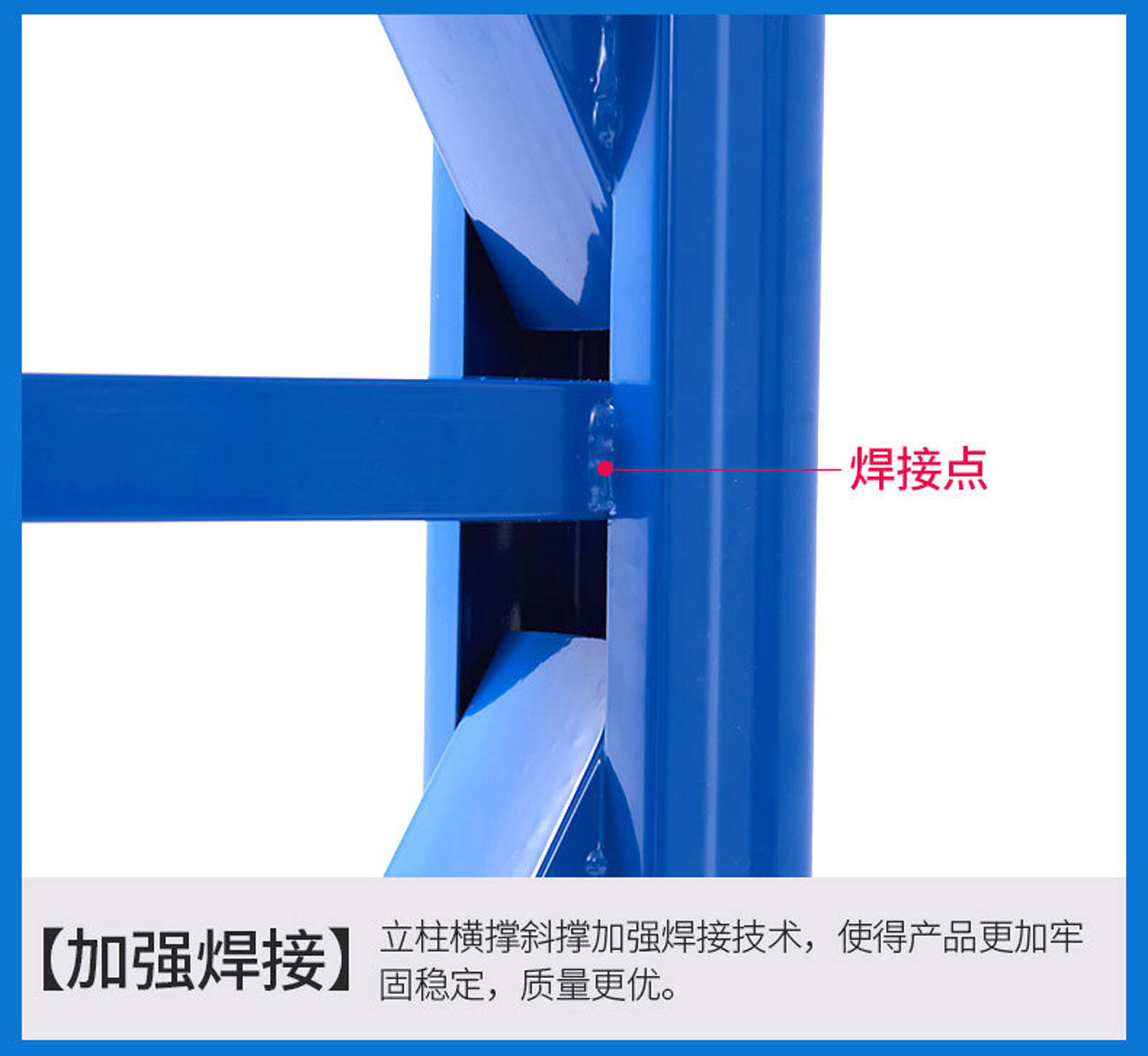

Strengthen welding:

The column, horizontal brace and diagonal brace are strengthened with welding technology, making the product more solid and stable with better quality.

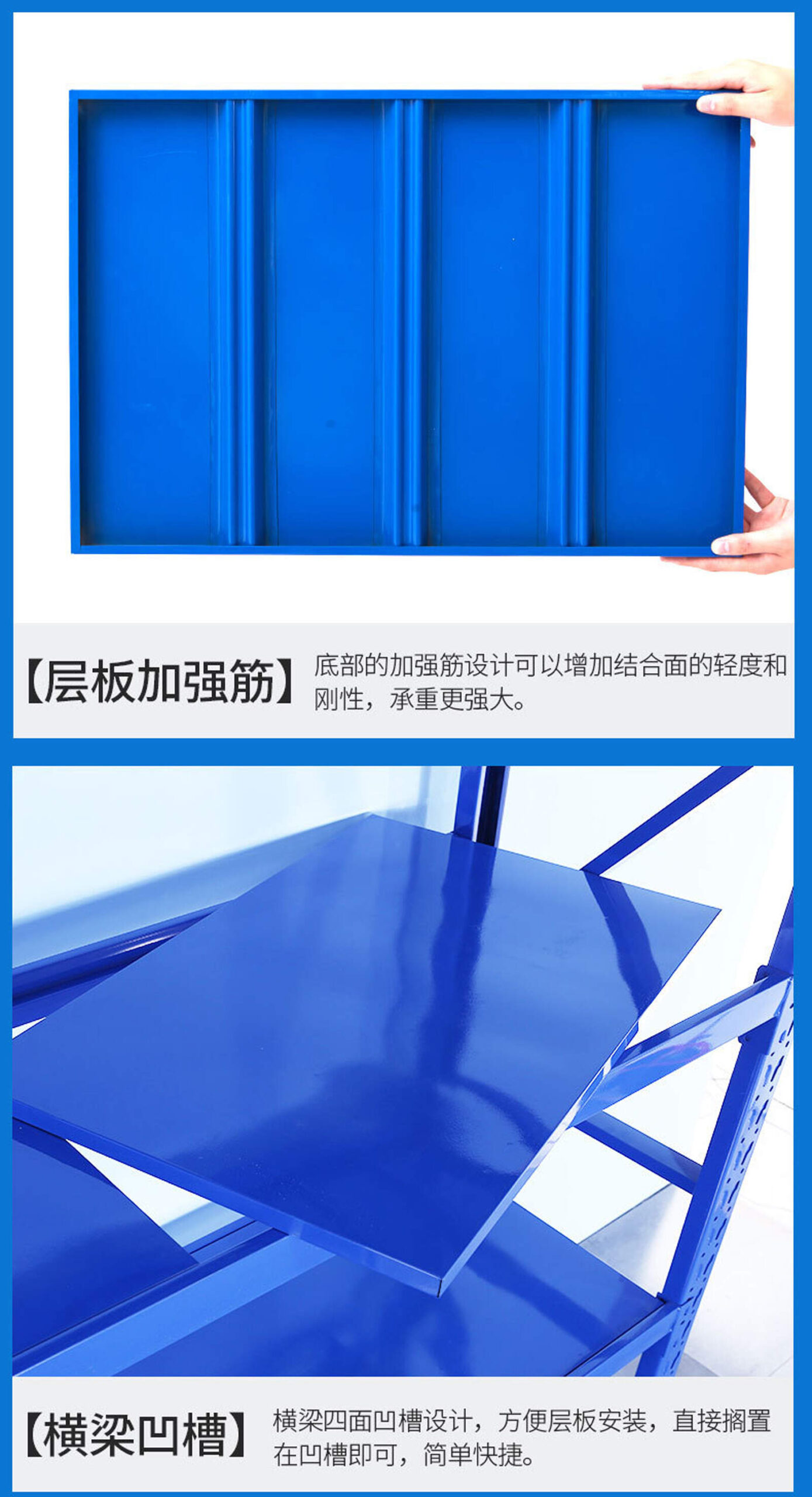

Shelf reinforcement ribs:

The bottom reinforcement rib design can increase the lightness and rigidity of the joint surface, and has a stronger load-bearing capacity.

Beam grooves:

The grooves on the four sides of the beam are designed to facilitate the installation of the shelves. Just place them directly in the grooves, which is simple and quick.

Customer Cooperation Cases

We provide customers with free professional storage solutions, planning large capacity in a small space.

Expand storage capacity, improve warehouse capacity utilization, and meet diverse storage needs.

Intelligent high-bay warehouses utilize automated equipment such as stackers and AGVs to achieve 24-hour uninterrupted operations, with efficiency 5-10 times that of manual labor. Stackers move at a speed of 3 meters per second with a positioning accuracy of ±5 mm, enabling high-density storage and rapid operations, improving storage capacity and operational efficiency.

The shelf height of the intelligent three-dimensional warehouse can reach 40 meters, and the storage capacity per unit area is increased by 5-10 times, which significantly reduces the land rental cost. In addition, the automated process reduces manual operations and reduces labor costs.

Intelligent high-bay warehouses are highly automated and can execute tasks quickly and accurately. Real-time data monitoring and tracking functions enable real-time monitoring of inventory status, transportation status, and equipment operating conditions, improving the accuracy and reliability of cargo handling.

Intelligent three-dimensional warehouses enhance data analysis capabilities through information systems and big data technologies, provide strong support for warehouse management decisions, optimize inventory management strategies, and improve capital turnover efficiency.

The intelligent three-dimensional warehouse system can quickly adjust storage strategies according to business needs, support a multi-variety and small-batch production model, enhance the company's market responsiveness, and with the development of technology and market changes, the system can be continuously upgraded and optimized.