Leave a message

Product parameters:

Application: Widely used in food industry, construction industry, third-party logistics and distribution centers

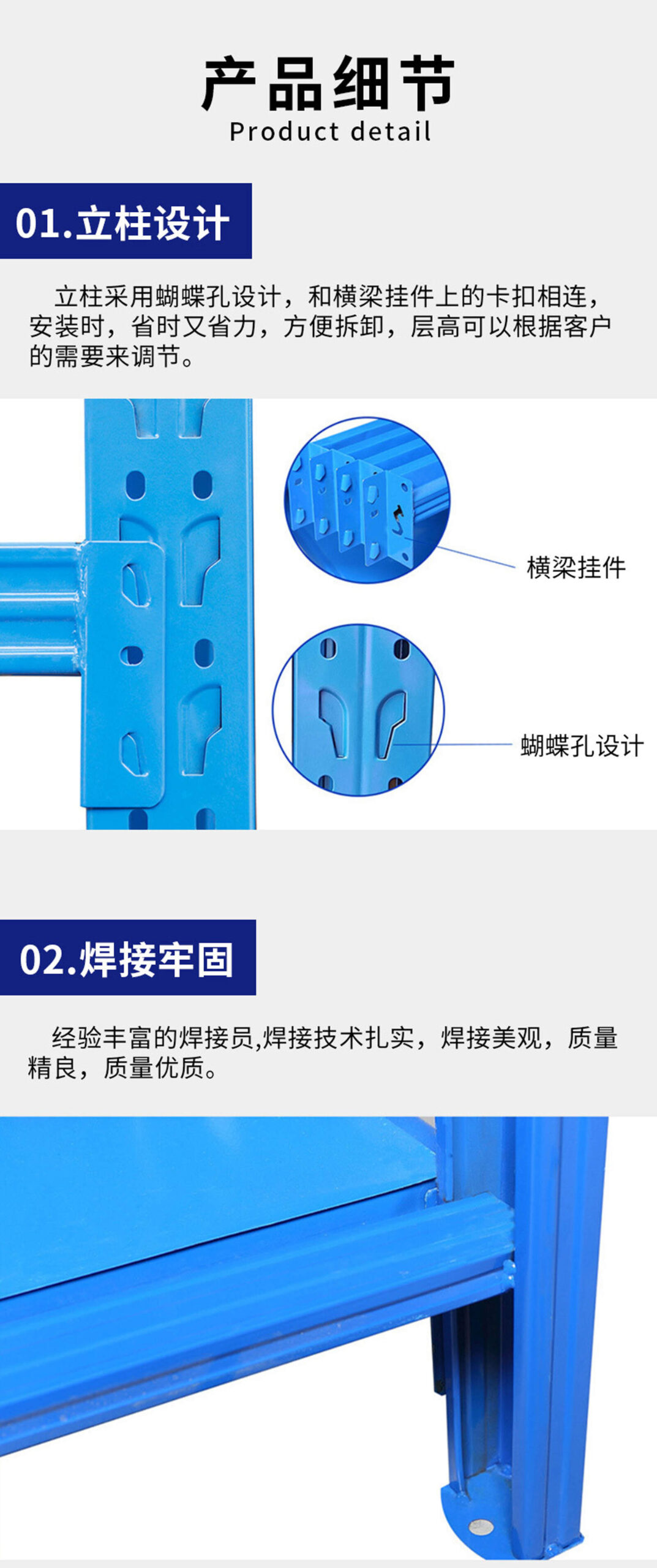

Product material: Q235 cold rolled

Product layers: 4 layers (can be increased or decreased)

Product size: Customized products are supported

Color: White/Gray/Blue/Black

Loading capacity: 100-500KG

Product appearance: Environmentally friendly electrostatic spraying, smooth and burr-free

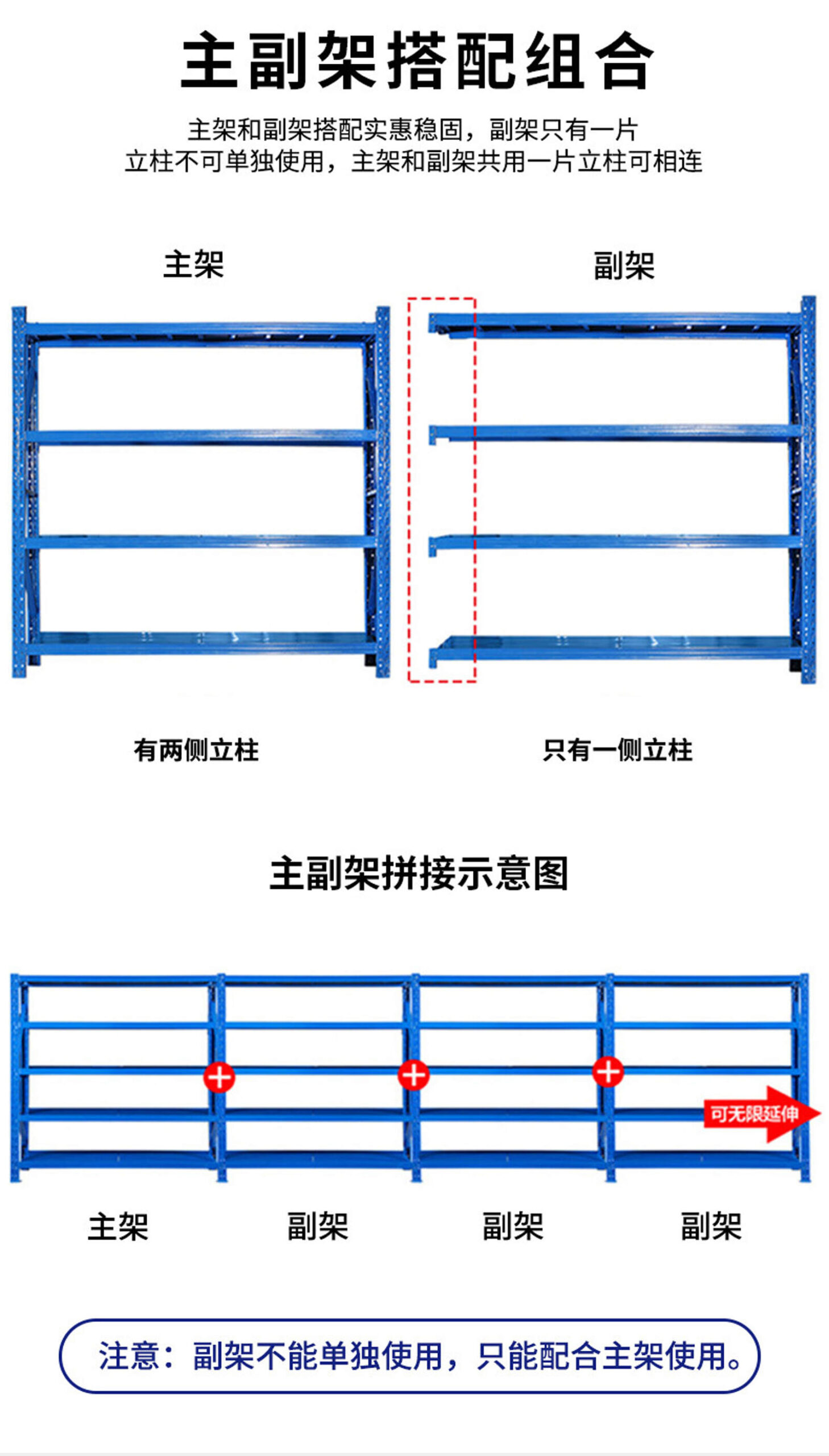

Main frame accessories: 2 columns + 8 beams + 8 shelves

Sub-frame accessories: 1 column + 8 crossbeams + 8 shelves

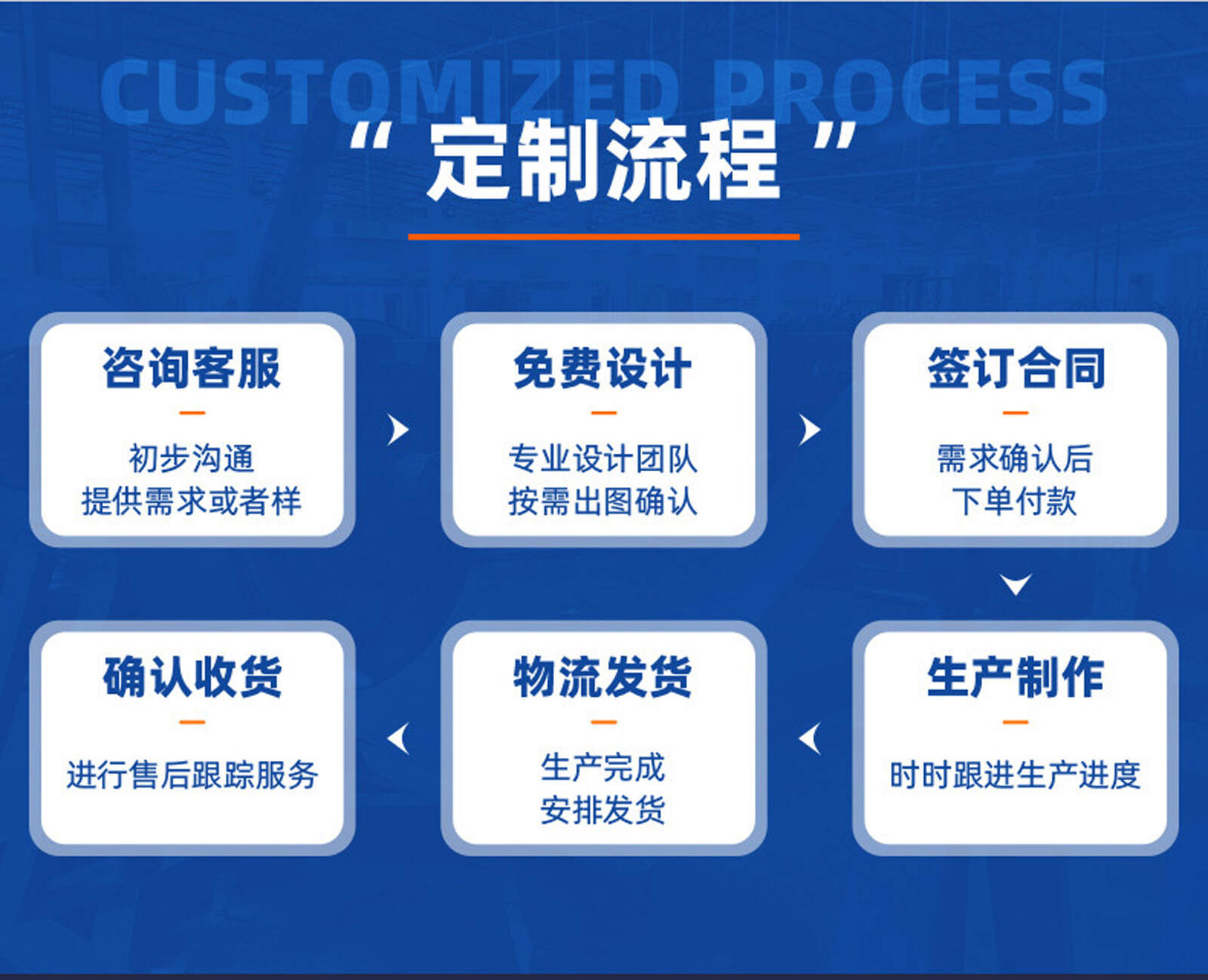

Customization process

Confirm receipt: Provide after-sales tracking service

Consult customer service: Initial communication to provide requirements or samples

Free design: Professional design team will provide drawings for confirmation upon request

Signing the contract: Place order and pay after demand confirmation

Production: Follow up the production progress at all times

Logistics delivery: Arrange delivery after production is completed

Intelligent high-bay warehouses utilize automated equipment such as stackers and AGVs to achieve 24-hour uninterrupted operations, with efficiency 5-10 times that of manual labor. Stackers move at a speed of 3 meters per second with a positioning accuracy of ±5 mm, enabling high-density storage and rapid operations, improving storage capacity and operational efficiency.

The shelf height of the intelligent three-dimensional warehouse can reach 40 meters, and the storage capacity per unit area is increased by 5-10 times, which significantly reduces the land rental cost. In addition, the automated process reduces manual operations and reduces labor costs.

Intelligent high-bay warehouses are highly automated and can execute tasks quickly and accurately. Real-time data monitoring and tracking functions enable real-time monitoring of inventory status, transportation status, and equipment operating conditions, improving the accuracy and reliability of cargo handling.

Intelligent three-dimensional warehouses enhance data analysis capabilities through information systems and big data technologies, provide strong support for warehouse management decisions, optimize inventory management strategies, and improve capital turnover efficiency.

The intelligent three-dimensional warehouse system can quickly adjust storage strategies according to business needs, support a multi-variety and small-batch production model, enhance the company's market responsiveness, and with the development of technology and market changes, the system can be continuously upgraded and optimized.