Rak Tugas Berat

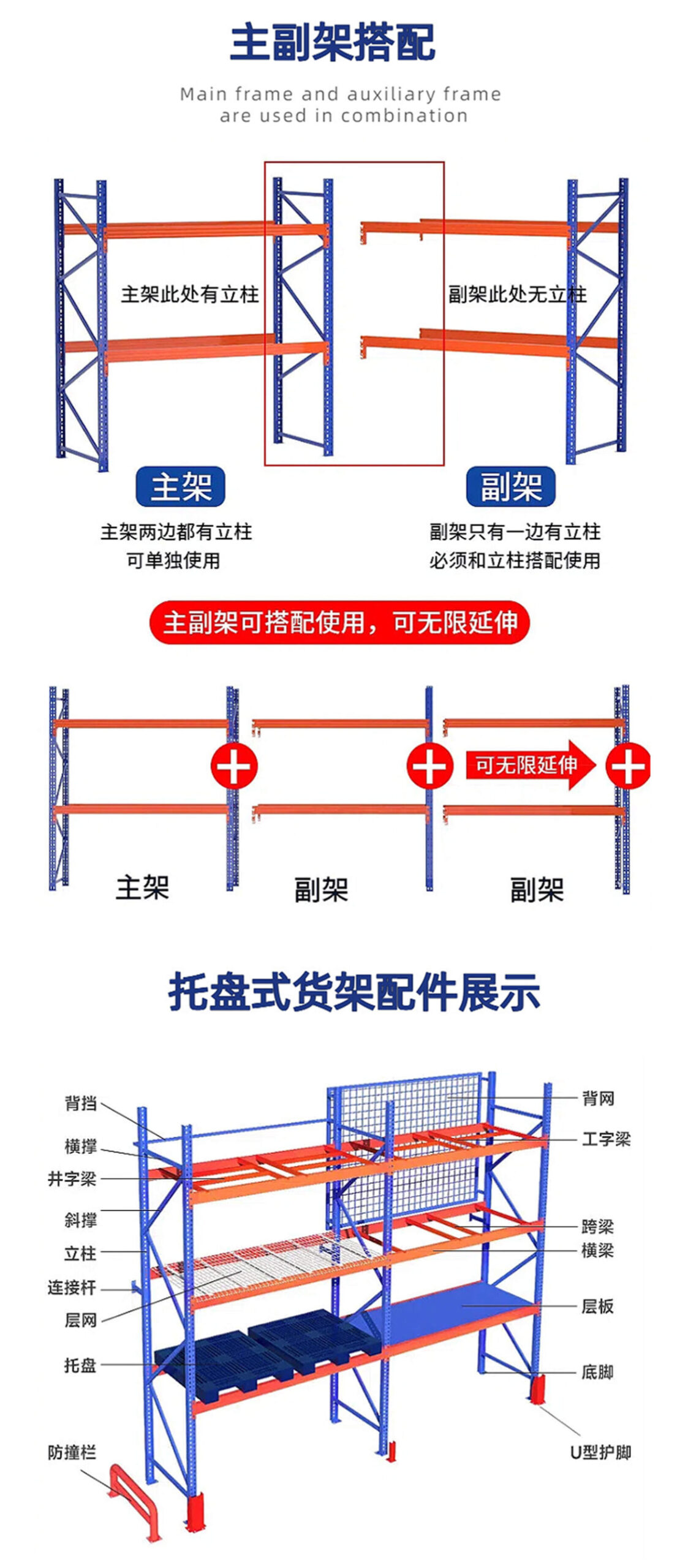

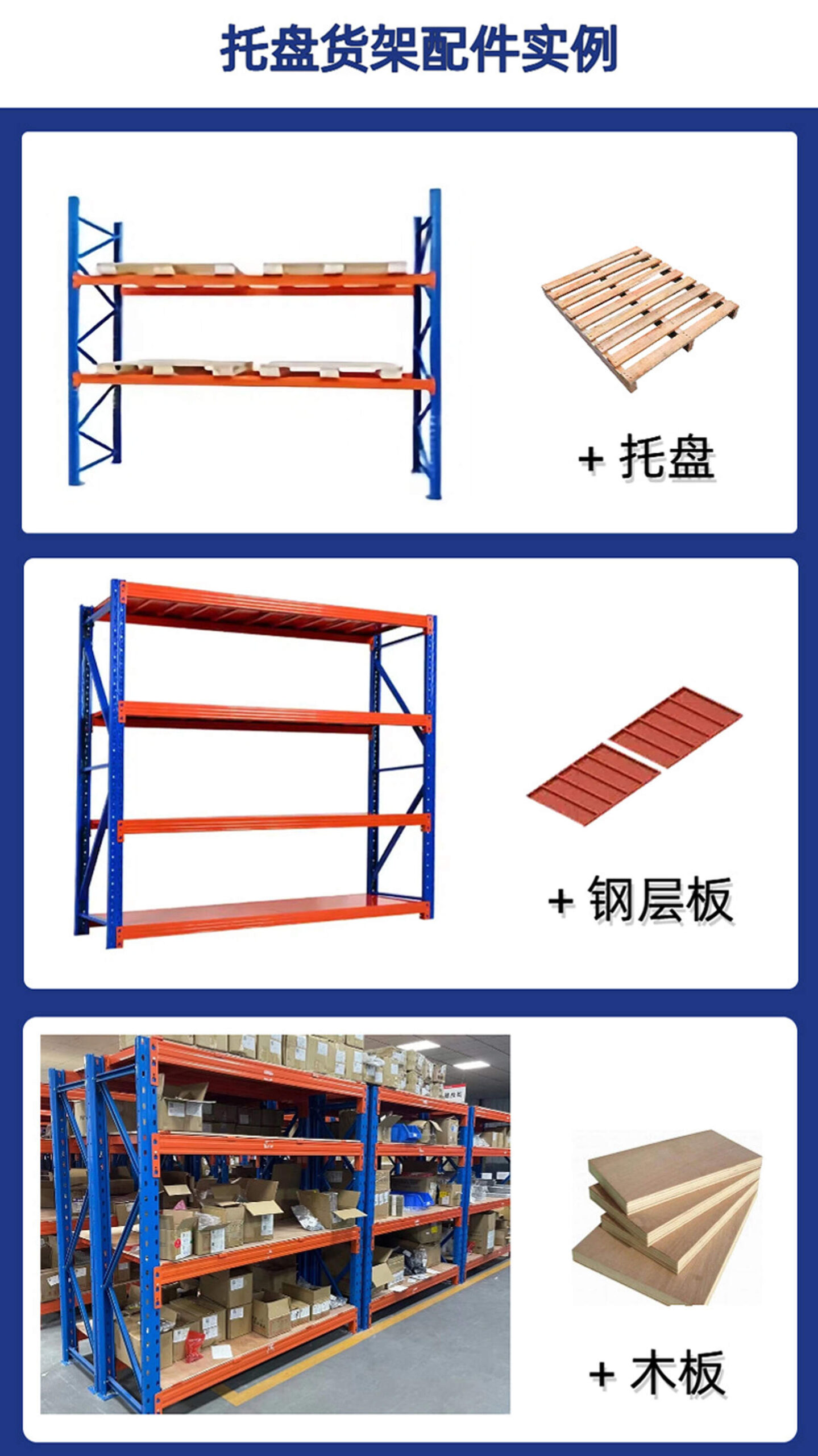

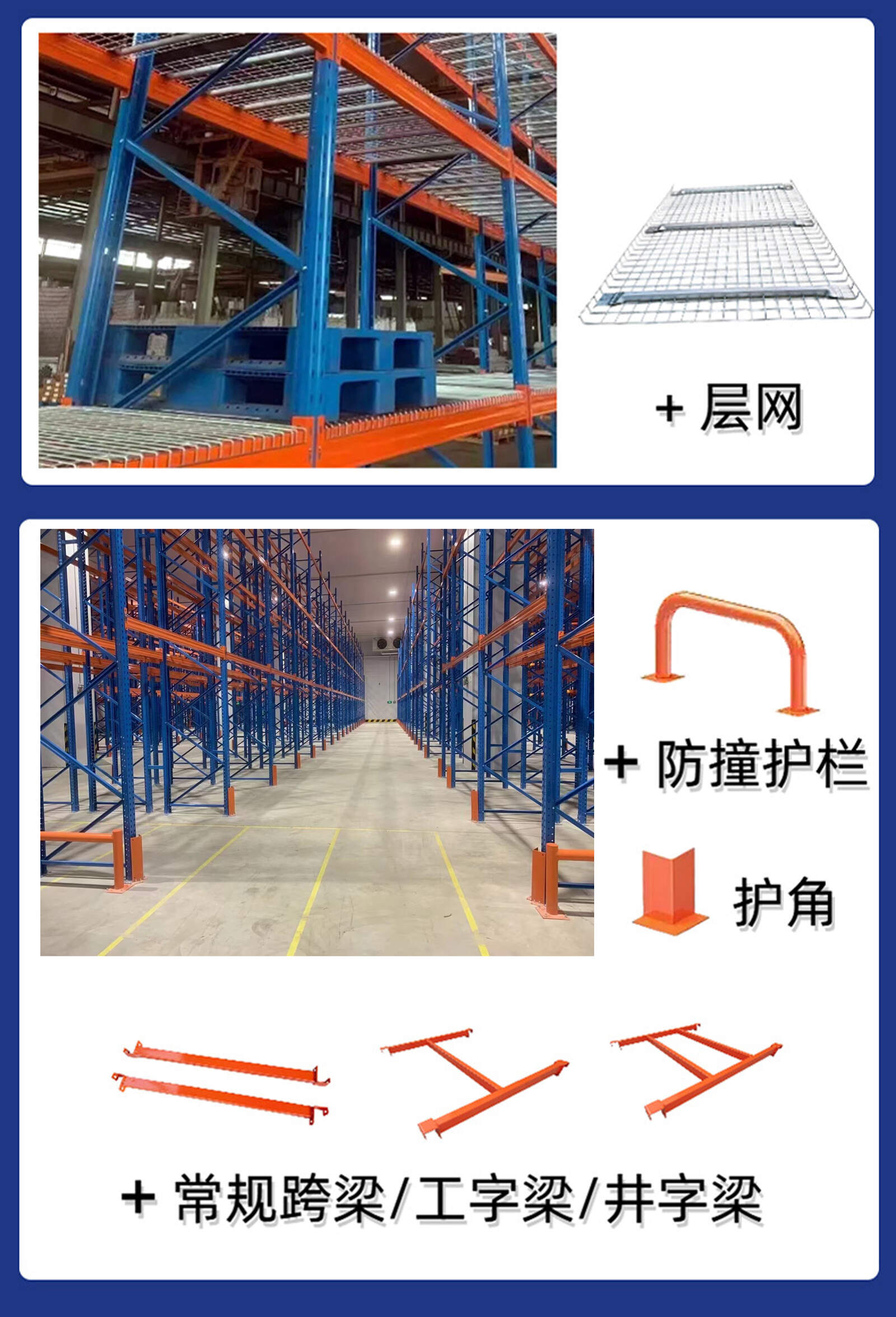

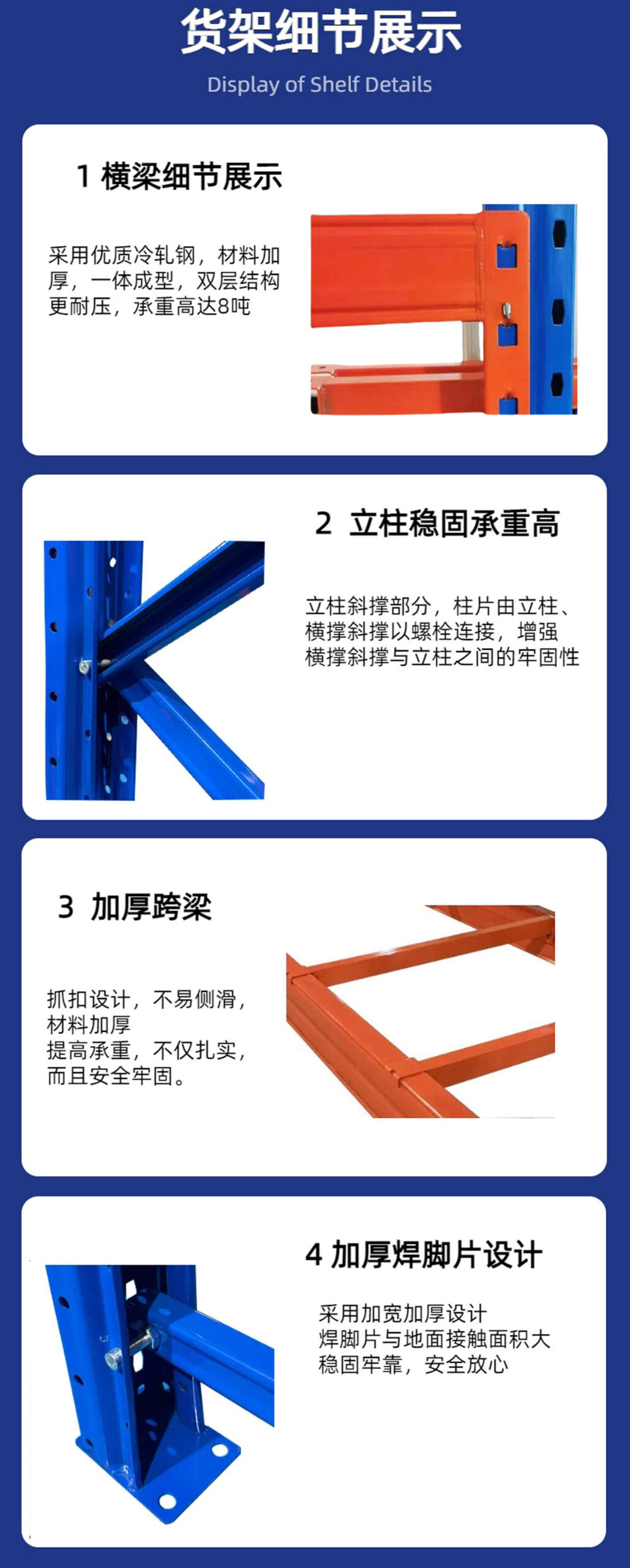

Rak tugas berat, juga biasa dikenal sebagai rak balok atau rak kargo, termasuk dalam kategori rak palet dan merupakan jenis rak yang paling umum di berbagai sistem rak penyimpanan domestik. Struktur yang dirakit sepenuhnya dalam bentuk potongan kolom + balok memiliki karakteristik ketinggian yang dapat disesuaikan, stabilitas yang kuat, dan pemanfaatan ruang yang tinggi. Itu terhubung ke kolom dengan kancing atau baut untuk membentuk bingkai pendukung yang stabil; rak-rak tersebut sebagian besar adalah panel jaring baja atau braket kayu, yang secara efektif dapat membubarkan tekanan barang dan meningkatkan daya dukung secara keseluruhan. Rak tugas berat banyak digunakan di perusahaan besar, gudang manufaktur, pusat distribusi logistik, dan bidang lainnya. Daya dukung bebannya yang kuat dan strukturnya yang stabil memungkinkannya untuk secara stabil mendukung penumpukan jangka panjang berbagai komoditas berat seperti bahan baku industri, mesin dan peralatan, produk kimia, dll., Dan secara efektif menghindari kecelakaan keselamatan yang disebabkan oleh deformasi atau runtuhnya rak.

Tinggalkan pesan

50+ Desainer Senior Paket desain komprehensif gratis sesuai dengan kebutuhan pelanggan

Pengukuran di tempat Berikan alamat untuk pengukuran dan pemasangan di tempat

Desain solusi pergudangan Desainer profesional, desain gambar solusi CAD

Pemasangan dari pintu ke pintu Tim pemasangan profesional, pemasangan dari pintu ke pintu

Proses yang disesuaikan Layanan eksklusif satu-ke-satu untuk memastikan produksi dan purna jual yang bebas dari rasa khawatir

Proyek rak laminasi tugas berat untuk industri perangkat keras

Proyek rak drive-through industri kimia

Proyek rak palet industri elektronik

Proyek rak balok industri listrik

Proyek Rak Pallet Industri Kimia

Proyek rak tipe tembus industri tekstil

Gudang high-bay yang cerdas menggunakan peralatan otomatis seperti stacker dan AGV untuk mencapai operasi 24 jam tanpa gangguan, dengan efisiensi 5-10 kali lipat dari tenaga kerja manual. Stacker bergerak dengan kecepatan 3 meter per detik dengan akurasi pemosisian ±5 mm, memungkinkan penyimpanan dengan kepadatan tinggi dan pengoperasian yang cepat, meningkatkan kapasitas penyimpanan dan efisiensi operasional.

Ketinggian rak gudang tiga dimensi yang cerdas dapat mencapai 40 meter, dan kapasitas penyimpanan per unit area meningkat 5-10 kali lipat, yang secara signifikan mengurangi biaya sewa lahan. Selain itu, proses otomatis mengurangi operasi manual dan mengurangi biaya tenaga kerja.

Gudang high-bay yang cerdas sangat otomatis dan dapat menjalankan tugas dengan cepat dan akurat. Fungsi pemantauan dan pelacakan data waktu nyata memungkinkan pemantauan status inventaris, status transportasi, dan kondisi pengoperasian peralatan secara real-time, sehingga meningkatkan akurasi dan keandalan penanganan kargo.

Gudang tiga dimensi yang cerdas meningkatkan kemampuan analisis data melalui sistem informasi dan teknologi data besar, memberikan dukungan kuat untuk keputusan manajemen gudang, mengoptimalkan strategi manajemen inventaris, dan meningkatkan efisiensi perputaran modal.

Sistem gudang tiga dimensi yang cerdas dapat dengan cepat menyesuaikan strategi penyimpanan sesuai dengan kebutuhan bisnis, mendukung model produksi multi-variasi dan batch kecil, meningkatkan daya tanggap pasar perusahaan, dan dengan perkembangan teknologi dan perubahan pasar, sistem dapat terus ditingkatkan dan dioptimalkan.