Heavy Duty Shelves

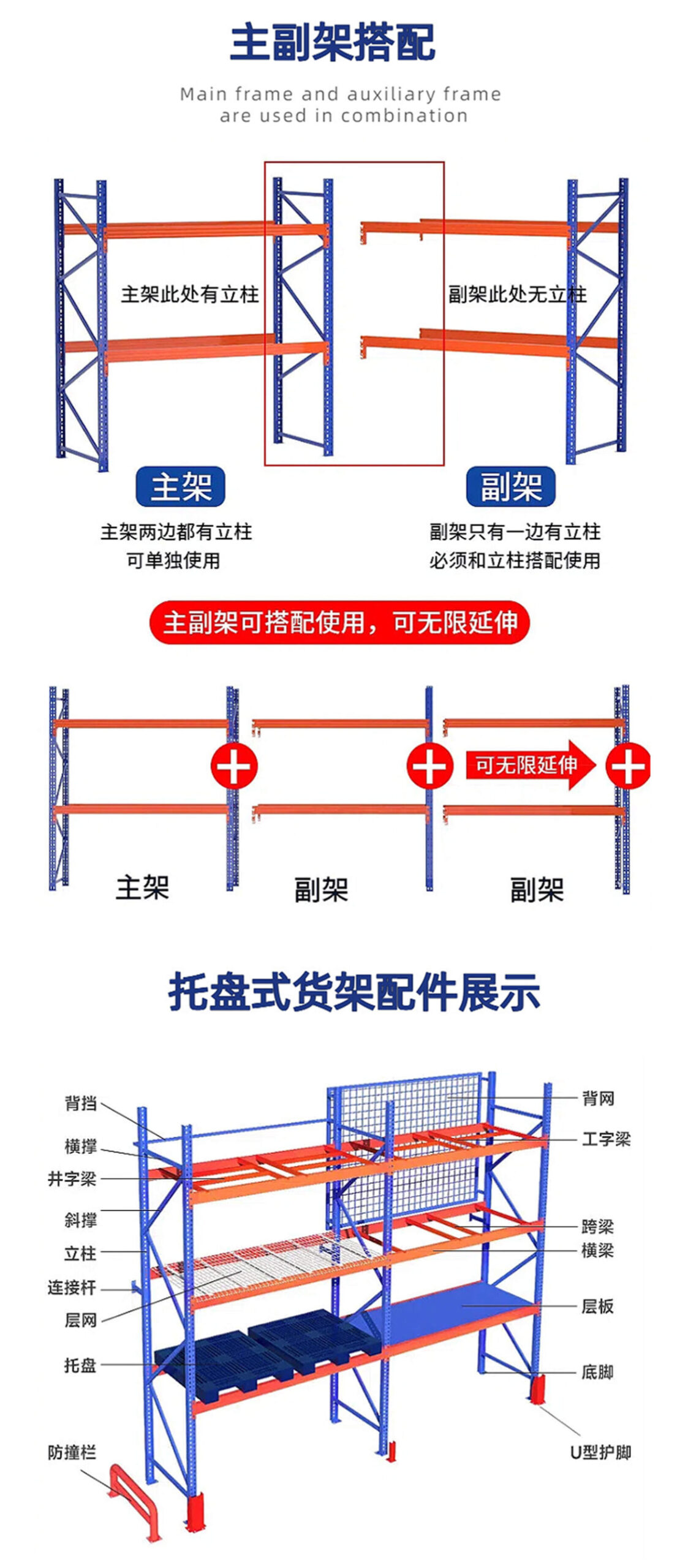

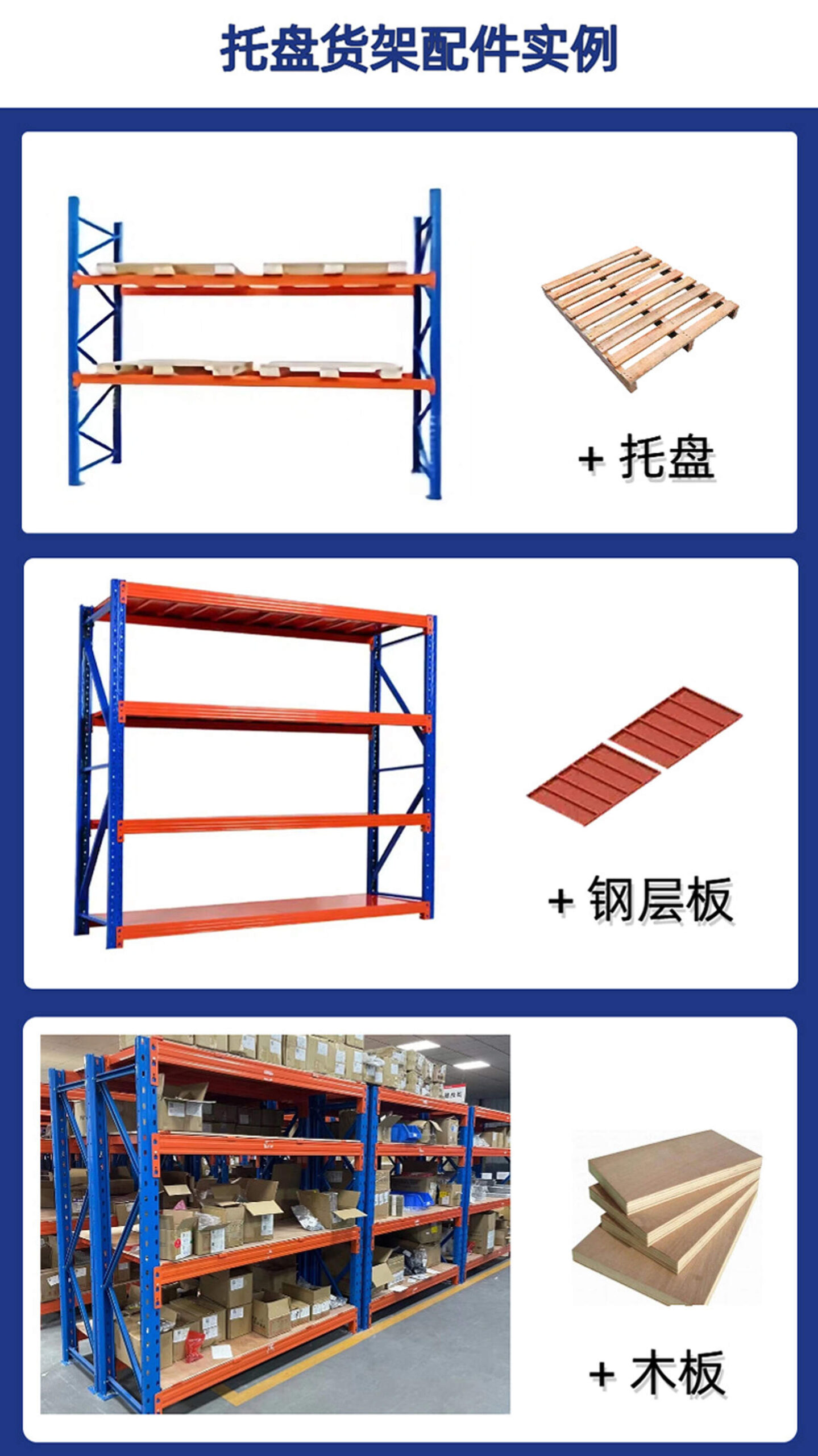

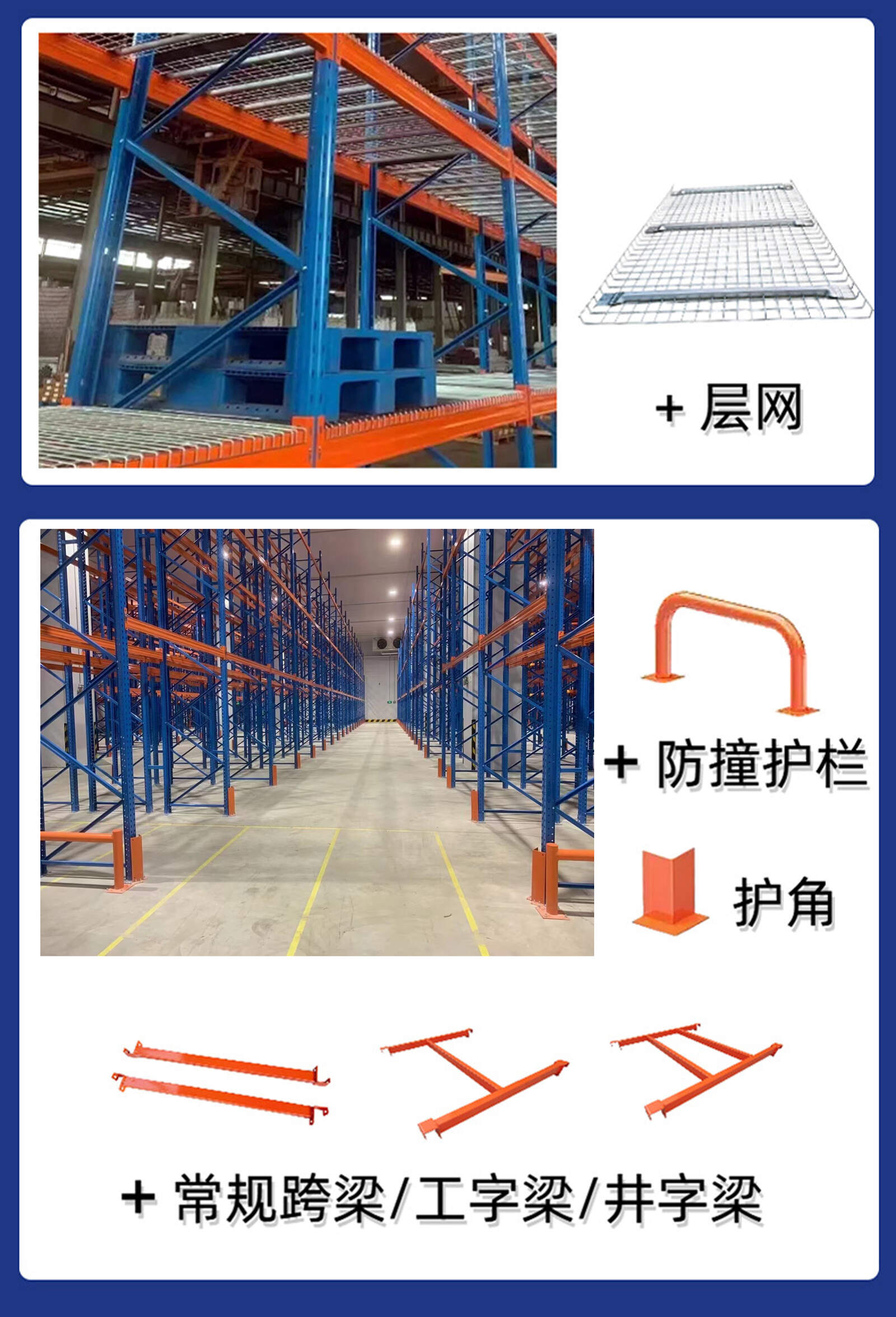

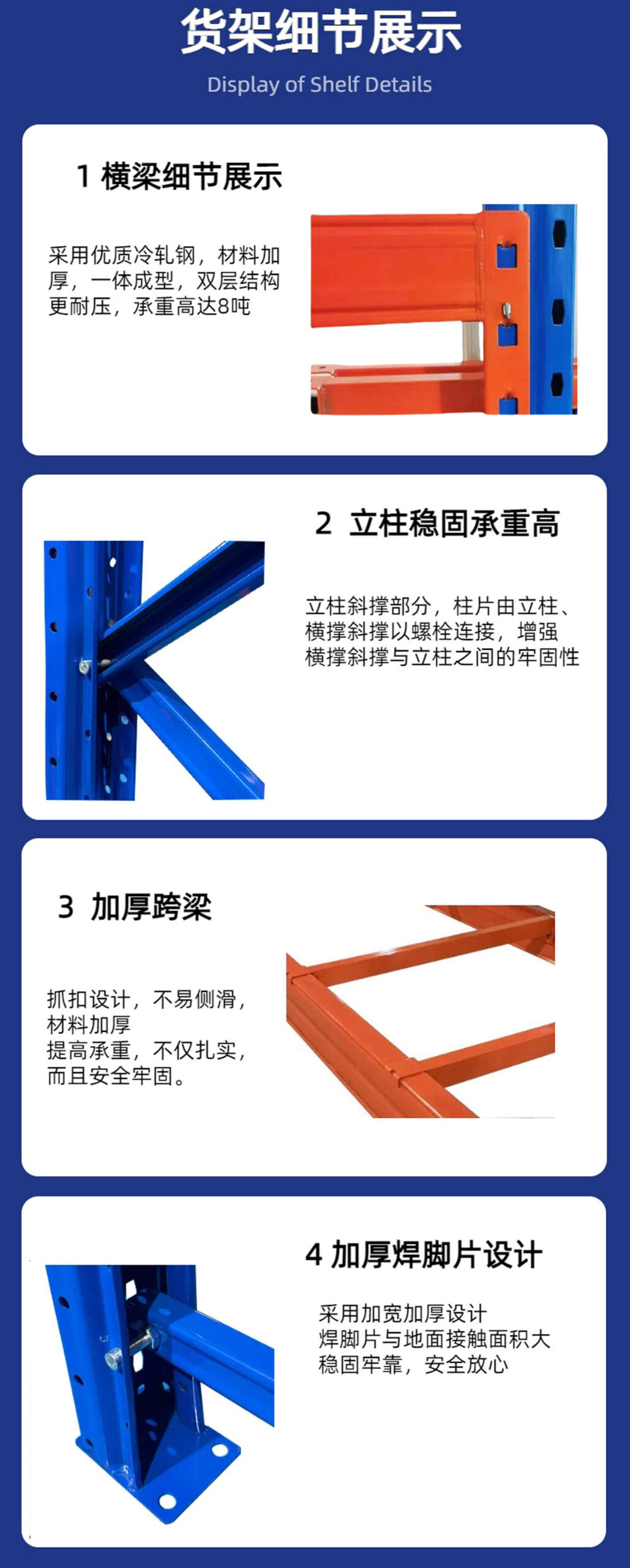

Heavy-duty racks, also commonly known as beam racks or cargo racks, belong to the category of pallet racks and are the most common type of racking in various domestic storage racking systems. The fully assembled structure in the form of column pieces + beams has the characteristics of adjustable height, strong stability, and high space utilization. It is connected to the columns by snaps or bolts to form a stable support frame; the shelves are mostly steel mesh panels or wooden brackets, which can effectively disperse the pressure of goods and improve the overall bearing capacity. Heavy-duty racks are widely used in large enterprises, manufacturing warehouses, logistics distribution centers and other fields. Its strong load-bearing capacity and stable structure enable it to stably support the long-term stacking of various heavy commodities such as industrial raw materials, machinery and equipment, chemical products, etc., and effectively avoid safety accidents caused by deformation or collapse of the shelves.

Leave a message

50+ Senior Designers Free comprehensive design plan according to customer needs

On-site measurement Provide the address for on-site measurement and installation

Design warehousing solutions Professional designers, design CAD solutions drawings

Door-to-door installation Professional installation team, door-to-door installation

Customized process One-to-one exclusive service to ensure worry-free production and after-sales

Heavy-duty laminate shelves project for the hardware industry

Chemical industry drive-through rack project

Electronics industry pallet rack project

Electrical industry beam shelf project

Chemical Industry Pallet Racking Project

Textile industry through-type shelf project

Intelligent high-bay warehouses utilize automated equipment such as stackers and AGVs to achieve 24-hour uninterrupted operations, with efficiency 5-10 times that of manual labor. Stackers move at a speed of 3 meters per second with a positioning accuracy of ±5 mm, enabling high-density storage and rapid operations, improving storage capacity and operational efficiency.

The shelf height of the intelligent three-dimensional warehouse can reach 40 meters, and the storage capacity per unit area is increased by 5-10 times, which significantly reduces the land rental cost. In addition, the automated process reduces manual operations and reduces labor costs.

Intelligent high-bay warehouses are highly automated and can execute tasks quickly and accurately. Real-time data monitoring and tracking functions enable real-time monitoring of inventory status, transportation status, and equipment operating conditions, improving the accuracy and reliability of cargo handling.

Intelligent three-dimensional warehouses enhance data analysis capabilities through information systems and big data technologies, provide strong support for warehouse management decisions, optimize inventory management strategies, and improve capital turnover efficiency.

The intelligent three-dimensional warehouse system can quickly adjust storage strategies according to business needs, support a multi-variety and small-batch production model, enhance the company's market responsiveness, and with the development of technology and market changes, the system can be continuously upgraded and optimized.